Digital innovation and, in particular, artificial intelligence (‘AI’)/ machine learning (‘ML’), are creating new opportunities to improve existing processes.

Here at Greycon, we are constantly keeping up-to-date with new technologies looking for such opportunities to enhance our software, in order to improve our clients’ production efficiencies.

Constantine Goulimis, Chairman of Greycon, has been researching how machine learning can integrate with Greycon’s software, X-Trim, and whether it can advance manufacturing processes.

‘Back in 2015, machine learning (ML) was still a new concept, certainly not as in vogue as it is now. With popularity comes easy-of-use, and it’s now astonishingly easy to use a ML framework. We began to apply it to the following question:

Given a particular solution, can ML accurately predict the minimum number of patterns for equivalent (= same waste) solutions?

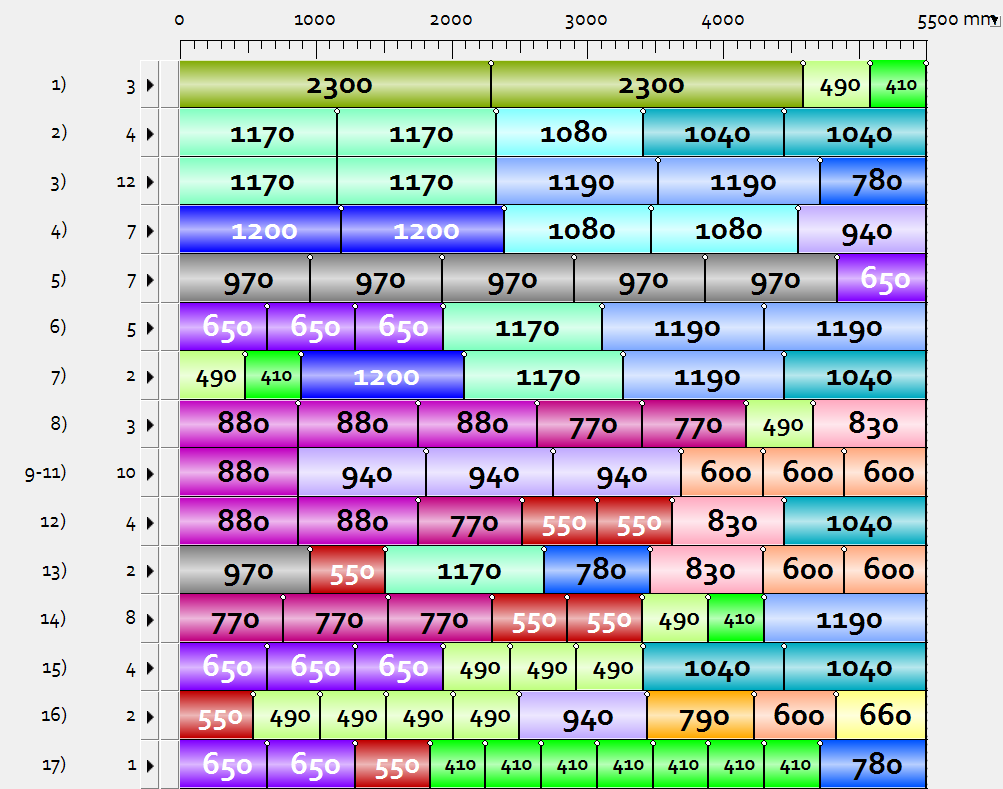

In simple terms, does knowing the details of the top picture (Fig. 1) allow ML to predict that 8 patterns (as shown in Fig. 2) are sufficient? Does the technology that appears to correctly count the number of faces in a photograph work in this case?

With my colleague Gastón Simone, Senior Development Engineer, we are investigating the possibility of answering this question. First, we had to build a dataset generator. Contrary to many published papers, orders in our industry do not have a uniform distribution of sizes. Once you have sorted the generation of the input data, you then have to solve it to get to the initial solution (Fig.1) and then apply our proprietary pattern-reduction optimisation to get to the number of patterns on the right. That being said, having dedicated a repurposed powerful computer, we have spent more than 100 hours on just the data generation step, creating several thousand instances.

So far, and the process is still on-going, we have found that:

- You do need thousands of instances to get even basic accuracy.

- Even with thousands of instances, so far, ML does not outperform a naïve model (which can be summarised, somewhat crudely, as “The minimum number of patterns is 0.7 × initial number of patterns”). The qualification “so far” is important, because even in the last few days, ML’s MAPE has dropped from 11.6% to 9.6%. Still, the naïve model achieves ~7.8%.

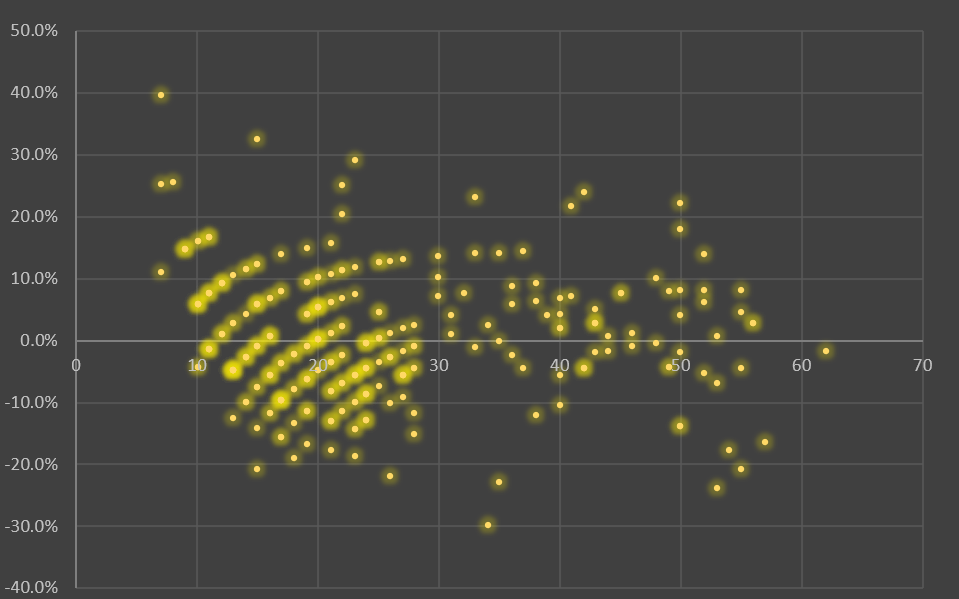

In the process, some quite beautiful charts have emerged, such as the error distribution as a function of the number of initial patterns:

(There is a reason why points lie on hyperbolas, it’s to do with the fact that the number of patterns in a solution is integer).